The Generative paddle is a product of the design process that uses advanced digital design technologies with local craft. The local connection is through the marine field. It starts with my love for the sea, through Naval Jewish roots such as the Zvolon tribe, to "Hamada shipyard"- the biggest paddle manufacturer in Israel, located in the heart of the old city of Acre. Under the influence of those, the project combines two tools from the technological digital world- Generative design (GD) and 3D printing. Those tools complement each other; 3D printing enables very complex forms, and GD allows a range of design varieties. Therefore, combining them originates unique and surprising results.

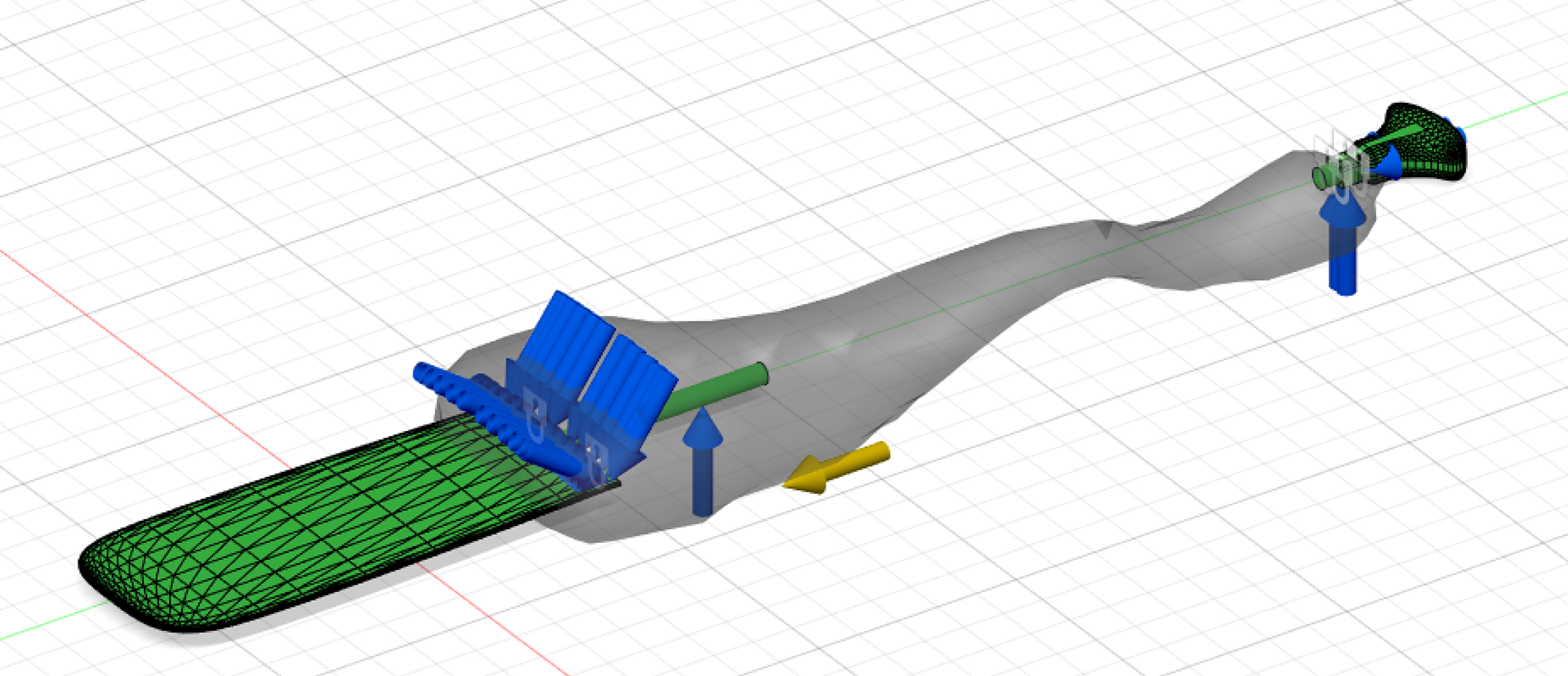

The GD process in the project started from learning the requirements and forces applied to the paddle. Then implement them in the GD software (Fusion 360), getting multiple design outcomes, choosing the well-suited GD result, and starting the process of designing the paddle on the base of the GD result. In a way, it is a design dialogue of me as a designer on one side and the AI of the software on the other side. In my opinion, this combination represents the design future in which working together with technology will lead to upgraded products that we have not seen.

Size: 152.5*17.3*6 cm

Programs: Fusion 360, Flashprint, Simplify 3d.

Manufacturing methods: 3D print, carpentry.

Manufacturing machines: 3DP Workbench 300 pro FFF 3d printer, Flashforge Creator printer, Dremel, table sander.